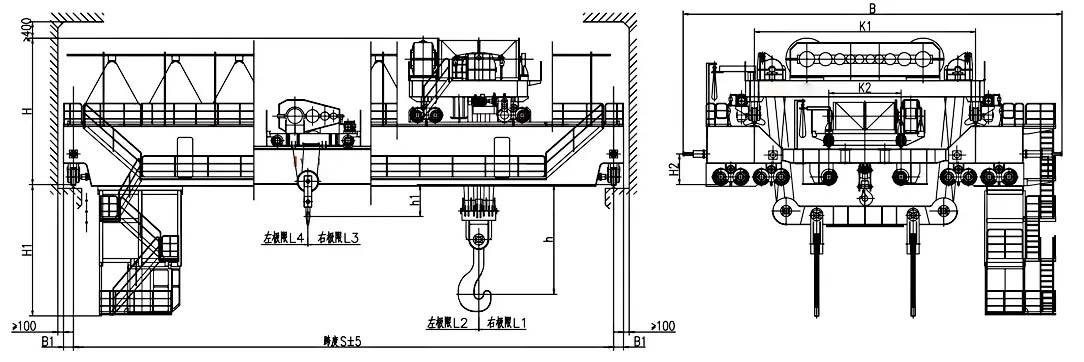

YZ four-beam stell foundry casting bridge crane is a high-performance lifting equipment designed for the metallurgical and casting industries. Its structure mainly includes the main beam, end beam, lifting trolley, trolley running mechanism and electrical control system.

Main beam and end beam constitute the main frame of the foundry casting crane. They usually adopt a box-shaped structure with high strength and rigidity, and can withstand heavy loads and impact loads. Tracks are laid on the main beam for the lifting trolley to run. The end beams are connected to both ends of the main beam to support the entire bridge crane and enable it to move along the factory track.

The lifting trolley is the core component, including the lifting mechanism, running mechanism and hoisting device. The lifting mechanism realizes the lifting and lowering of heavy objects, and the running mechanism enables the trolley to move along the main beam track. The hoisting device is designed according to specific needs.

The trolley running mechanism is installed on the end beam and consists of a motor, a reducer and wheels to drive the crane to move longitudinally along the factory track. The electrical control system is responsible for coordinating the operation of various mechanisms, usually including the main control cabinet, operating table and safety protection devices.

Its overall structural design fully considers the harsh conditions of the metallurgical casting environment such as high temperature and dust. Foundry casting crane adopts heat-resistant and dust-proof materials, and is equipped with multiple safety protection measures to ensure the reliability and durability of the equipment under complex working conditions.