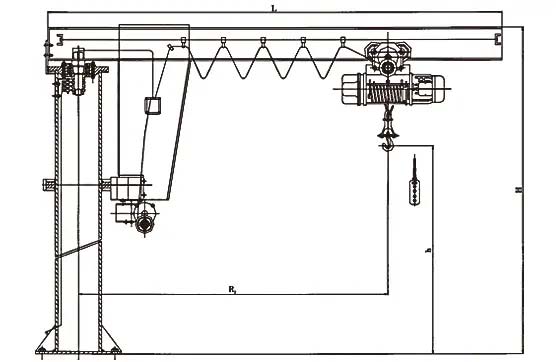

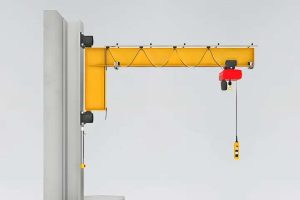

BZ Type Floor Mounted Jib Crane

Floor mounted jib crane is a common use light duty jib crane with electric hoist. The column is the supporting part of the entire cantilever crane, usually made of metal (such as steel). The column needs to have sufficient strength and stability to withstand the various forces. Its bottom is generally firmly fixed to the ground or other basic structures to ensure stable performance. The cantilever is a horizontal structural component extending from the column. Its length varies according to different usage requirements and can extended within a certain range to facilitate lifting operations in different working areas. The structural design of the cantilever takes into account the ability to withstand the weight of the heavy object and the torque and other forces during the lifting process.

The slewing device is at the connection between the column and the cantilever, allowing the cantilever to slew within a certain angle range. The slewing device usually uses slewing bearings to achieve flexible and smooth rotation, making it convenient to move the lifted load accurately to the target position.

Application

Manufacturing industry

In workshops of machinery manufacturing, automobile manufacturing and other industries, floor mounted jib crane is to move parts, raw materials, etc. For example, it could move small processed parts from one machine tool to another, or moving raw materials from the warehouse to the production line.

Warehousing logistics

It is for loading, unloading and stacking of goods in the warehouse. It can easily lift or put down goods from the shelves, improving the utilization rate of storage space and the efficiency.

Maintenance workshop

In equipment maintenance workshops, it could lift and move heavier equipment parts to facilitate maintenance personnel to perform maintenance operations. For example, in the maintenance of large mechanical equipment, damaged parts are lifted for replacement or repair.

Features

High flexibility: Since the cantilever can rotate and retract, it can cover a large working area in a relatively small space. This makes it very suitable for places where space is limited but multi-point lifting operations are required

Easy to operate: Can easily control the lifting, rotation and cantilever extension on the ground or on a suitable operating platform. Moreover, the operation interface is relatively simple.

Simple installation: The column cantilever crane is easier to install. It does not require complex foundation engineering. Generally, it only needs to firmly fix the column on the ground or a suitable foundation. The installation cycle is short and it can be put into use quickly.

Low cost: Both the purchase cost of the equipment and the installation and maintenance costs are relatively low. Its structure is relatively simple, and the cost of parts is not high.