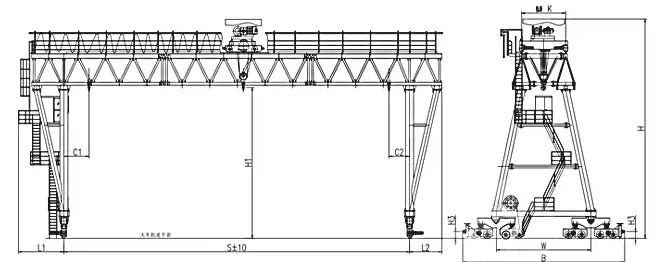

MG Double Girder Truss Gantry Crane

MG double girder truss gantry crane is a tried and tested solution for the lifting demands in outdoor construction sites. With the winch trolley on the two parallel truss girder, Weihua double truss gantry crane provides strong and steady lifting capability. Thanks to the high precision welding robots, the truss girder shows great stiffness against the heavy load.

Specialized for practical needs, our truss gantry crane includes a number of innovative features which benefit in the long term. It features a reliable design and incorporates many engineering details:

- High rigidity of steel structures with a low deadweight

- Advanced modular design and secure connection at each joint

- Easy installation, maintains and dismantle

- Low wind drags thanks to the truss structure

- Compatibility with various accessories to lift different cargos

- Full support of Weihua AICrane system which significantly improves working efficiency

Application

Ports: For loading and unloading of containers, cargo ships, etc., to improve logistics efficiency.

Shipbuilding industry: Hull assembly, disassembly and other operations, because it can handle very heavy parts.

Steel industry: Suitable for the handling and loading and unloading of large items such as steel plates and steel.

Water conservancy construction: Including the lifting of heavy equipment and materials in the construction and maintenance of dams, channels, etc.

Mines: used for the transportation and loading and unloading of resources such as ore and coal.

Features

Thanks to the truss structure, our Construction MG features light deadweight and many other strongpoints. The low wind drags makes the gantry crane stand still on the open field of construction yards. The modular design provides ease of assembly, dismantle, maintains and transport. Being different from traditional gantry cranes with box girders, wind blows through the truss girder with low friction, maintaining stability in strong winds.

Our AICrane system also makes the crane see things, intelligently identifying humans from cargo before brake in time to improve not only working efficiency, but also safety.