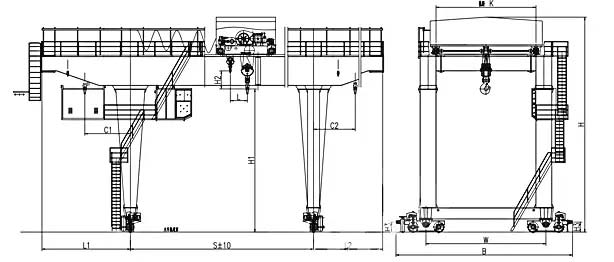

U-Type Double Girder Gantry Crane

The U-type double girder gantry crane is mainly for general loading, unloading, and lifting operations. It has increased the design of the small trolley track gauge, resulting in a larger legroom and suitable for handling larger items like containers, etc. Due to its structure, this gantry crane eliminates the need for a saddle frame compared to the A-type gantry crane.

With a fixed lifting height, the overall height of the machine is lower than A-type. And the rail distance of its electric trolley is big, which means better operational stability and load distribution. All the design makes it excellent performance and adaptability in multiple working sites. Its supporting legs increase stability and allows the equipment to move freely on the ground.

Application

U-type gantry crane is suitable for general loading, unloading, and lifting operations in open-air freight yards and along railway lines. The normal operating environment of this series of U-type double girder gantry crane should be within the range of 25℃~+40℃. And the average temperature within 24 hours should not exceed 135℃. And and the average temperature within 24 hours should not exceed 135℃.

At container terminals, U type double girder gantry cranes could transfer containers from cargo ships to yards or trucks. They are capable of handling containers of different sizes and can be turned around quickly to increase efficiency. Besides containers, U gantry cranes can also load and unload bulk cargo, large machinery and other heavy items.

In the steel plants, timber mills, etc., U shape double beam gantry cranes provide efficient lifting solutions for users

Features

Unique U-shaped frame: With a stable “U”-shaped structure, providing good bending and torsional rigidity and enhancing the overall stability.

Efficient control system: It could achieve quick response and smooth operation, improving work efficiency and operating accuracy.

High lifting capacity: Particularly suitable for lifting overweight objects, such as ship components, wind power equipment, etc.

Large span coverage: To cross multiple tracks or working areas, increasing working flexibility and adapting to complex and changing working conditions.